Technical Support

Friction Welding

Rotary Friction Welding: This is most commonly used method in friction welding. In rotary friction welding a rotating component is pressed against a stationary component to achieve bonding. This type of friction welding is suitable for carbon steel and other metal applications. Dissimilar materials can also be joined by this technique.

Linear Friction Welding: Friction welding achieved by the linear relative motion across the interface is named linear friction welding. This type of welding is suitable for components that are difficult to join by other welding techniques. It is successfully used in aerospace industry to join complex parts such as turbine blades in gas turbines.

Friction Welding

Spin Welding: This type of friction welding is generally used for thermoplastic materials where the material in the vicinity of the interface softens and moves outwards as a result of spinning and pressure. Once a homogeneous layer of soft material is available at the interface sufficient force is applied to join the parts together.

Friction Stir Welding: Friction stir welding is achieved by a non-consumable tool that does not soften during the operation. The tool is pressed on the interface of the components to be welded together. The tool softens both of the components around the interface and mixes the softened material from both of the component around the interface to provide bonding.

Applications

Inertia Friction Welding: In inertia friction welding the required energy for the joining the components is obtained from the stored kinetic energy in a flywheel or the welding machine. One of the components is held stationary while the other component is attached to the rotating flywheel. As soon as the components are brought into contact the kinetic energy of the flywheel is converted into frictional heat that is used for the welding of the components.

OEM Accepted

Factory also could produce according customer’s samples or Drawings. Process as follows:

Company Profile

Founded in 2009, AL-STEEL Group is one of the leading companies which specializes in Friction Welding Technologies. There are nearly 100 staff in our company, among them are 9 technicians and senior engineers. Adhering to the management concept of technological innovation and quality first, we have laid a solid foundation both at home and abroad and become a well-known professional brand in China. We always believe that quality, service and innovation are the principles of development. We have made great efforts to build our brand first and that we have got great achievements. High quality, excellent performance, good service and competitive price to win the satisfaction of customers and the market.

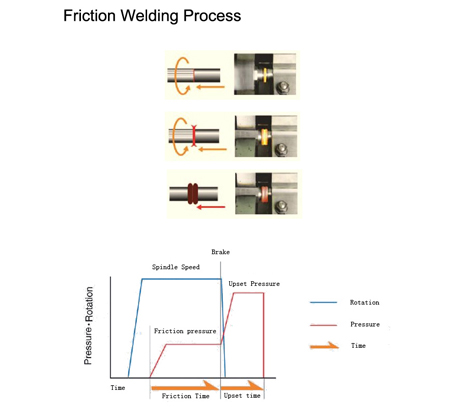

Friction welding is a solid state bonding process which leads to the coalescence of materials under the influence of the heat generated by the mechanically-induced sliding motion between rubbing surfaces. The parts to be joined are held together under pressure. Mechanical friction may be produced between a moving work piece and a stationary component, two moving components or using a moving tool. There are several types of friction welding: linear friction Welding, rotary friction welding and friction stir welding, these technologies are widely used in automotive, oil machinery, bimetal, aerospace, military and conventional industries. Our friction welding machines occupy an prominent position.

Copyright © AL-STEEL Group Co., Ltd. All Rights Reserved | Sitemap